With the support of D&TS and the international ECLASS Standard, Diehl Defence, a leading supplier of high-tech defense equipment, has taken a decisive step toward digital transformation. By harmonizing and classifying over 96,000 material master records, Diehl has significantly improved data quality, automated processes, and increased efficiency. This success story demonstrates how strategic master data management can provide a competitive advantage.

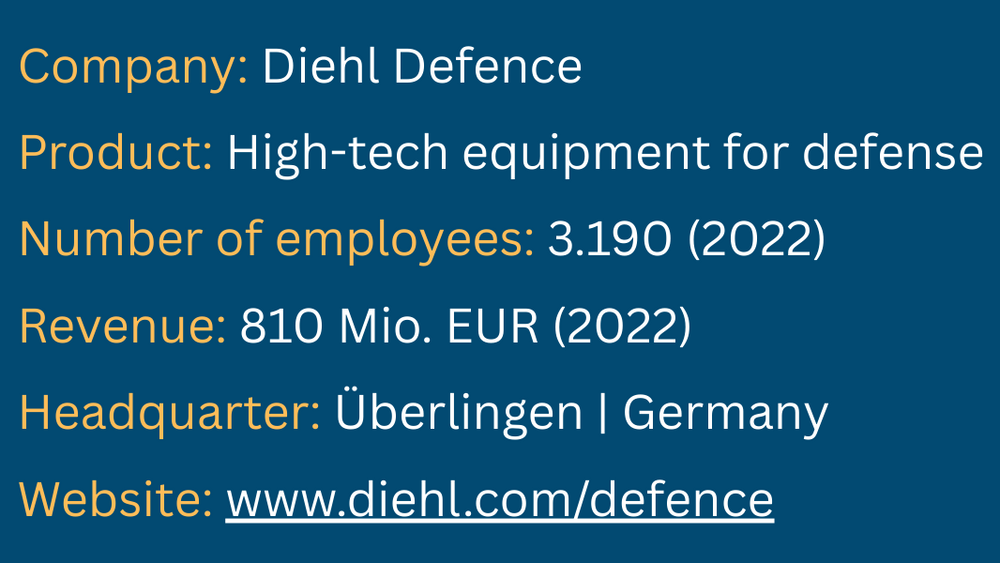

Diehl Defence supplies high-tech equipment for defense. With the development and manufacture of guided missiles and ammunition for the army, air force, and navy, the company is one of the technology leaders on the global market. A new addition to its range is modern system solutions for ground-based air defense. Innovative solutions in the fields of reconnaissance, surveillance, training, and protection round off the product spectrum.

At the end of 2020, Diehl Defence conducted a needs analysis of the search options and tools used for the current material search, drawing from several workshops. The survey focused on employees in development, design, and component management. The assessment validated typical problems in the departments, such as poor data quality, duplicate entries, time-consuming searches, and incorrect or redundant information in ERP and PDM/PLM systems. There were also cases of no search results, resulting in unnecessary new entries. Based on these challenges, optimization potential was identified and defined.

The goal was to reduce waste in material procurement caused by long search times, part variations, cumbersome processes, and poor information flow.

The "Material Pool" project

To realize their potential, the team at Diehl Defence first harmonized and cleaned up the "material pool" and classification data from the primary system (SAP). Implementation required a suitable classification management solution. They chose ECLASS over the company's own maintenance-intensive classification structure because of the advantages offered by the ISO conform ECLASS Standard. Diehl Defence aims to eliminate manual classification and optimize processes by exchanging standardized product data. Additionally, the wide range of the standard's properties aims to improve data quality.

Intensive research began. Then, certified ECLASS providers that met the requirements were compared in a selection process.

ECLASS professionals sought and found

"With their in-depth understanding of and extensive experience with the ECLASS Standard, D&TS proved to be the perfect partner for our project."

(Michael Oswald, Inhouse Consultant, Diehl Defence)

The project approach

During the D&TS MDM Excellence Workshop, participants developed recommendations and action plans for the “Material Pool” project based on findings from the Diehl Defence Thinking Workshops and D&TS analyses.

The project began in 2021 with the goal of classifying and evaluating 96,000 material master records according to the ECLASS 11.1 Standard. The ECLASS properties sets were adapted to Diehl Defence's needs. Data records were enriched with additional information from the ClassCOCKPIT Knowledge Database, automatic extraction of data from technical data sheets, and manual processing by experts. Enriching the information posed a particular challenge in the categories of small electronic components and chemicals, which represent an important and quantitatively large material group in the defense industry. After classification, duplicates were identified and removed.

Data harmonization resulted in a uniform structure for product descriptions. This forms the basis for the future uniform generation of purchase order texts, among other things,

The ECLASS classification, which was implemented in the SAP system, replaced the previous internal classification. The customer successfully tested the new classification, including classes, characteristics, and evaluations, in the Q-System. Then, they transferred it to the production system without any problems using ClassCOCKPIT SAP.

The PARTsolutions parts management system for engineers was optimized, and materials were assigned to standard and purchased parts catalogs. This gives engineers direct access to intelligent 3D multiCAD models, such as those from Solid Edge and SolidWorks. Additionally, the parts search has improved with the mapping of the SAP classification in PARTsolutions and its regular synchronization with the ClassCOCKPIT Synchro tool. This optimizes not only the search for existing materials but also the search for new materials, including 3D models.

The result

Over the course of a year, Diehl Defence improved the level of standardization and data quality at three locations (Überlingen, Rötenbach, and Ingelfingen) with the support of experts from D&TS GmbH through Data Cleansing.

Introducing the international data standard ECLASS increased transparency throughout the supply chain and facilitated the digital exchange of information within the company (between departments and from human to machine) and externally (with partners, suppliers, and customers).

By implementing ClassCOCKPIT SAP, Diehl Defence took the first step toward automating processes digitally. The goal is to minimize human error and increase efficiency through simplified, rule-based processes.

Diehl Defence's optimized parts management system speeds up the material procurement process thanks to an improved search function that makes finding the required parts faster and more efficient. Efficiency is also increased by avoiding unnecessary new creations and redesigns.

With a revised material pool containing complete and valid data, Diehl Defence can now make data-driven decisions and partially automate data-intensive processes with technological solutions. This contributes to the implementation of digital transformation.

The outlook

To ensure high data quality for Diehl Defence in the long term, additional workflows for creating new materials are being implemented. D&TS was commissioned to take the next crucial step in the project, which will allow the processes of material creation and classification according to ECLASS to be handled directly via the D&TS outsourcing service. This frees up capacity for Diehl Defence's component management team, enabling them to focus on strategic tasks, such as discontinuation processes and supplier management. Diehl Defence regularly provides D&TS with material master data in the form of tickets via the ClassCOCKPIT Ticket system. D&TS then delivers process-compliant product master data (basic data and classification) directly to the SAP ERP system. A cost analysis showed that outsourcing creation and classification is significantly more cost-efficient than internal maintenance. Outsourcing also allows Diehl Defence to draw on D&TS's expert knowledge.

The initial project's success underscored the importance of thorough data cleansing and classification.