CAx User Guide

Table of Contents

- Common Aspects

- Identification - Identifikation

- Attached Information - Begleitende Information

- Information - Information

- Commercial - Kommerziell

- Mechanical and electrical construction

- CAx-Basis Aspect

- Aspect of connection and function (CAx)

- Examples

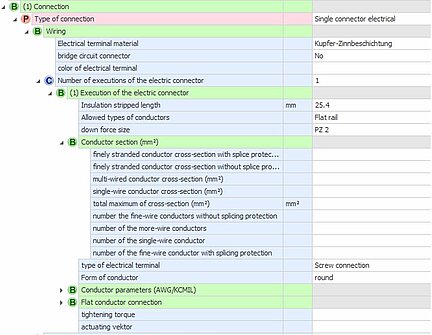

- How to describe terminals using ECLASS ADVANCED model

- Illustration of circuit diagram symbols

- Description of heavy-duty connectors (HDC)

Foreword

Saving process costs with ECLASS

Product master data in engineering

A medium-sized machine building company requires roughly 4,000 different electrical and automation technology products. Innovations and customer requirements increase this number by approximately 1% of new products every month. These products are from various manufacturers who, in most cases, only provide the commercial material master data – and in different formats. The technical data required for electrical engineering, for calculations and drawing symbols are not usually included; this information must be gathered laboriously from catalogs or created.

The effort involved in this is considerable. Depending on the complexity of the product, a designer needs between two and eight hours to create a master data record for engineering in an ECAD system. If, due to delivery obligations, different ECAD systems have to be maintained, this effort is multiplied accordingly because the various systems are not compatible with each other. If an entrepreneur uses additional automation measures, such as a drilling and machining center or wire production, the effort involved in providing this data will also be added. Each company creates this master data individually. Economically, this is a disaster. This effort is also an inhibitive barrier to introducing new products, such that innovative new products need more time to become established on the market.

For product manufacturers, providing engineering data documentation for every possible CAE system when launching a product on the market is an almost impossible task. Each ECAD system has a different format. In addition to product knowledge, knowledge of creating models in the corresponding ECAD systems is also necessary. Providing engineering data is therefore very time-consuming and expensive for product manufacturers.

For this reason, representatives of renowned product manufacturers (e.g. Eaton (Moeller), Phoenix Contact, Siemens, Weidmüller), CAE/CAD system vendors (e.g. AmpereSoft, Aucotec, Eplan, Wscad, Zuken) and additional interested parties formed an expert group within the ECLASS association in 2007. Drawing upon their expert knowledge, this group created the ECLASS standard – a description for products that is CAx-system-independent. This description type is not just limited to electrical engineering. It also takes into consideration the other areas of mechatronics technology connected with electrical engineering, such as pneumatics and hydraulics.

With ECLASS, this situation has changed fundamentally. ECLASS is the only ISO/IEC standard-compliant industrial standard in the world that classifies products and services unambiguously and that also describes them with characteristics – for example, it not only identifies a contactor as such, it also provides a unique description of its rated control supply voltage.

The ECLASS ADVANCED structure provides all data necessary for a complete component description for ECAD systems. That is, a component is described in its entirety – from the component master data, through the symbol description for the circuit diagram, right through to the description of the design for the control cabinet layout.

Using this standard, the manufacturer only has to classify each product once. The product master data, including technical properties and necessary documents, can therefore be reliably made available to the customers electronically based on the standard. When customers and suppliers use this ECLASS classification, they can easily work with and document the product data. This principle does not only apply to the CAE tools, it also applies to all applications involved in the business process.

ECLASS can do even more

In addition to the creation of product data, the search for the correct material as well as the maintenance and management of material master data that has been created multiple times costs a great deal of time, and therefore money. Once a material has been created, it is often the case that it cannot be bundled, replaced, and reused cost-efficiently in the systems because the internal rules necessary for the description of texts, translations, technical properties and standardized search structures not exist in most cases.

With approximately 41,000 product classes and 17,000 characteristics ECLASS covers the majority of traded goods and services directly. Many industry standards (e.g. from the electronics industry, medical technology, the construction industry, paper products / office technology) strive for interoperability in order that the potentials of a cross-industry classification standard can be utilized.

If ECLASS is used as the company-wide basis for the classification and description of products, it revolutionizes the engineering process through information consistency throughout the entire value added chain. Manual activities are minimized, and system-supported enquiry and purchasing processes for CAE and ERP systems become possible. Furthermore, ECLASS creates the prerequisite for many Industrie 4.0 applications. ECLASS is the descriptive language in engineering.

ECLASS use / applications

- Data exchange and data management for engineering

- Simple search for material and services thanks to the standardized catalog structure

- Generation of design plan symbols

- Generation of circuit diagram symbols

- Support of verification processes for IEC 61439-1, maintaining verification documents

- Support for calculating the power dissipation

- Use of data for drill automation and wiring routing

- Support for commercial processes, quotations and invitations to tender

For additional information on the ECLASS CAx expert group: Cross Expert Group CAx

Prerequisites, Information

The following two points are prerequisite for using ECLASS in engineering:

- The devices and products must have been classified and evaluated with the ECLASS Advanced classification.

- This data is transmitted with an electronic catalog in the BMEcat format 2005.1.

- The information relates to ECLASS as of version 8.0

In addition to the product data described with ECLASS, the BMEcat catalog also provides the opportunity to exchange commercial and logistical data. The user can decide to what extent this is relevant for the respective application. Along with a unique ID for identification in the form of a material or GTIN number, BMEcat contains two important product-describing elements:

Short description: <DESCRIPTION_SHORT lang="eng">xxxxxxxxxxx</DESCRIPTION_SHORT>; und die

Long description: <DESCRIPTION_LONG lang="eng">xxxxxxxxxxxx </DESCRIPTION_LONG>; wichtig.

These two descriptions can be exchanged in specific languages (lang) and are an essential component for the identification, selection, description and documentation of the services in many applications. For data delivery for CAD/CAE systems, we recommend providing the product descriptions in multiple languages in order that the documentation can be created for international customers.

Example:

<DESCRIPTION_SHORT lang="deu">Stromversorgung</DESCRIPTION_SHORT>

<DESCRIPTION_SHORT lang="eng">Power supply unit</DESCRIPTION_SHORT>

<DESCRIPTION_LONG lang="deu">Primär getaktete Stromversorgung QUINT POWER mit wählbarer Ausgangskennlinie, SFB Technology (Selective Fuse Breaking) und NFC-Schnittstelle, Eingang: 1-phasig, Ausgang: 24 V DC / 5 A</DESCRIPTION_LONG>

<DESCRIPTION_LONG lang="eng ">Primary-switched QUINT POWER power supply with free choice of output characteristic curve, SFB (selective fuse breaking) technology, and NFC interface, input: 1-phase, output: 24 V DC/5 A</DESCRIPTION_LONG>

Advanced relevant Elements

The following sections describe the universally relevant advanced elements of the ECLASS classes. Once they have been assigned to a class, these elements, divided into aspects and blocks with defined characteristic and characteristic block structures, always have the same structural design. This enables the different engineering systems to easily access the product properties that are relevant to CAx planning.

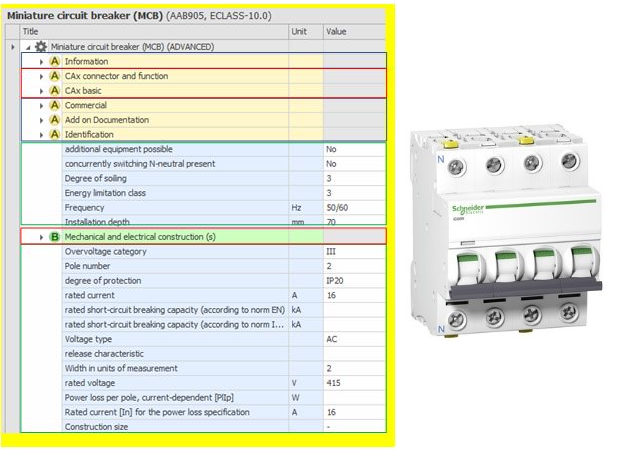

The classes themselves are differentiated by the class-specific technical characteristics:

These are normally the characteristics that are directly assigned to a class. These characteristics are used to describe a product with its selection-relevant data, e.g. to perform a selection of the products required by the user from a list of many devices by using the characteristics in an application.

Below are some examples:

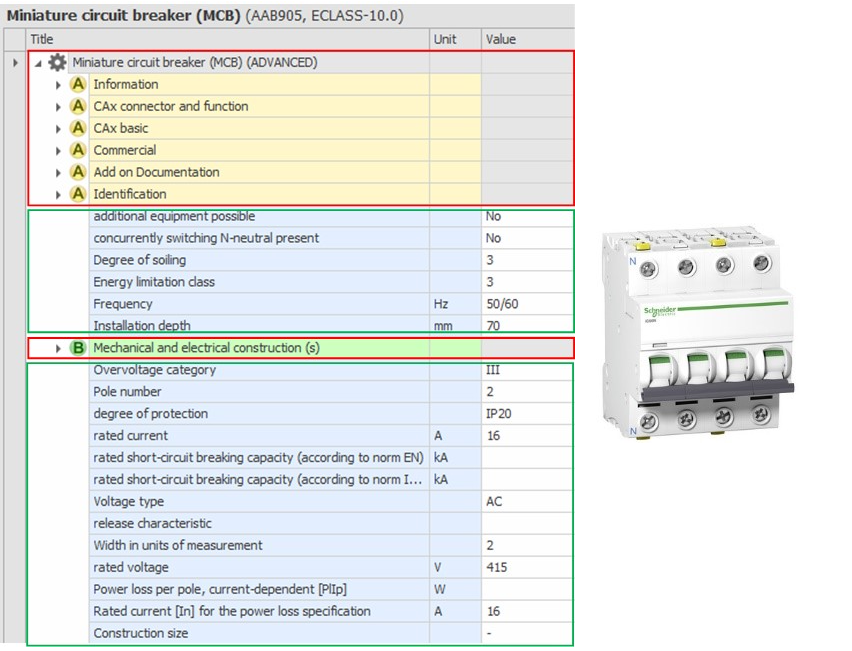

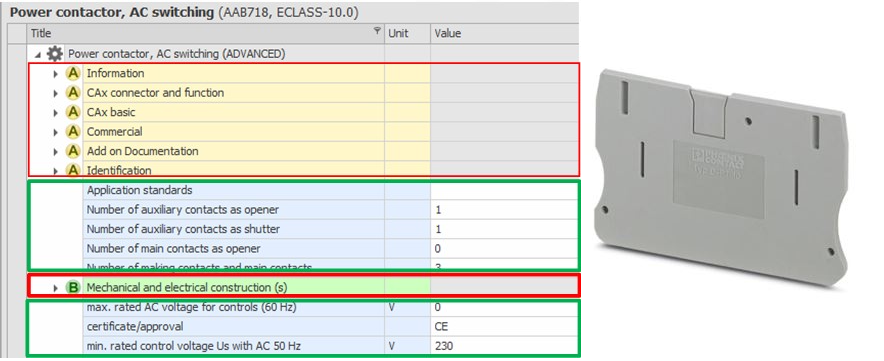

The red frame shows advanced aspects and blocks.

The green frame shows class-specific technical characteristics.

Explanation of terms:

| Term | Explanation |

|---|---|

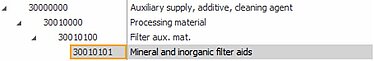

| ECLASS classification | Is a uniform order model (classification method) with which objects are classified in accordance with certain criteria, i.e. they are ordered into classes. |

| Classification example (structure) |  |

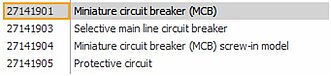

| Class | A class in the classification system is the structure element for the systematic assignment of objects with the same properties |

| Example of classes |  |

| Characteristic | Property of a class for describing a property of an assigned object. There are different types of characteristics. |

| Value | Specification of a property as text or numeric. Free assessment or from lists of standards. |

| Unit | Standardized unit of measure, e.g. acc. to ISO. |

| Example characteristics |  |

| Aspect | Subordinated subject-oriented compilation of characteristics and characteristic blocks that describe application-oriented properties and that are not class-specific. For example, CAx application, storage, transport |

| Example aspects |  |

| Characteristic block | Compilation of characteristics that describe a certain part of the object. For example, the dimensions. |

| Example block |  |

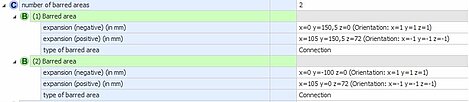

| Cardinality reference characteristic | References the corresponding equal number of blocks according to the object-specific assessment (quantity). |

| Cardinality example |  |

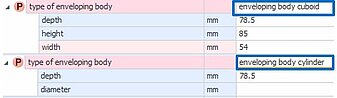

| Polymorphism reference characteristic | References different referenced blocks corresponding to the value according to the object-specific assessment (text). |

| Polymorphism example |  |

The table form is used to explain the content of the ECLASS structure elements described below. Reference is made to more extensive descriptions. The first column contains a level specification for the table for better understanding The second column lists the identifier for the type of structure element. Key: | |||||||

|---|---|---|---|---|---|---|---|

| Level | Type | Strukture element name | Application, Explanation | Function for CAx and process | |||

A | Aspect | ||||||

B | Block | ||||||

M | Characteristic | ||||||

W | Value | ||||||

C | Reference characteristic „Cardinality“ | ||||||

B | Block called up n times through | ||||||

P | Reference characteristic „Polymorphism“ | ||||||

W | Value of the reference characteristic for identifying the polymorphous block | ||||||

For information on further structure elements / characteristic types of the ECLASS classification, see: Category:Structure and structural elements

Data structure

The ECLASS ADVANCED CAx data structure supplement was designed by the expert group from the perspective of equipment and operating material, and not from the perspective of software programs for generating (e.g. in PLM / CMS systems) or processing (e.g. ECAD) the data.

The data structure supports the creation of complex device descriptions through referencing, application of versions and parts relationships. It therefore provides CAx-oriented support of the essential product applications.

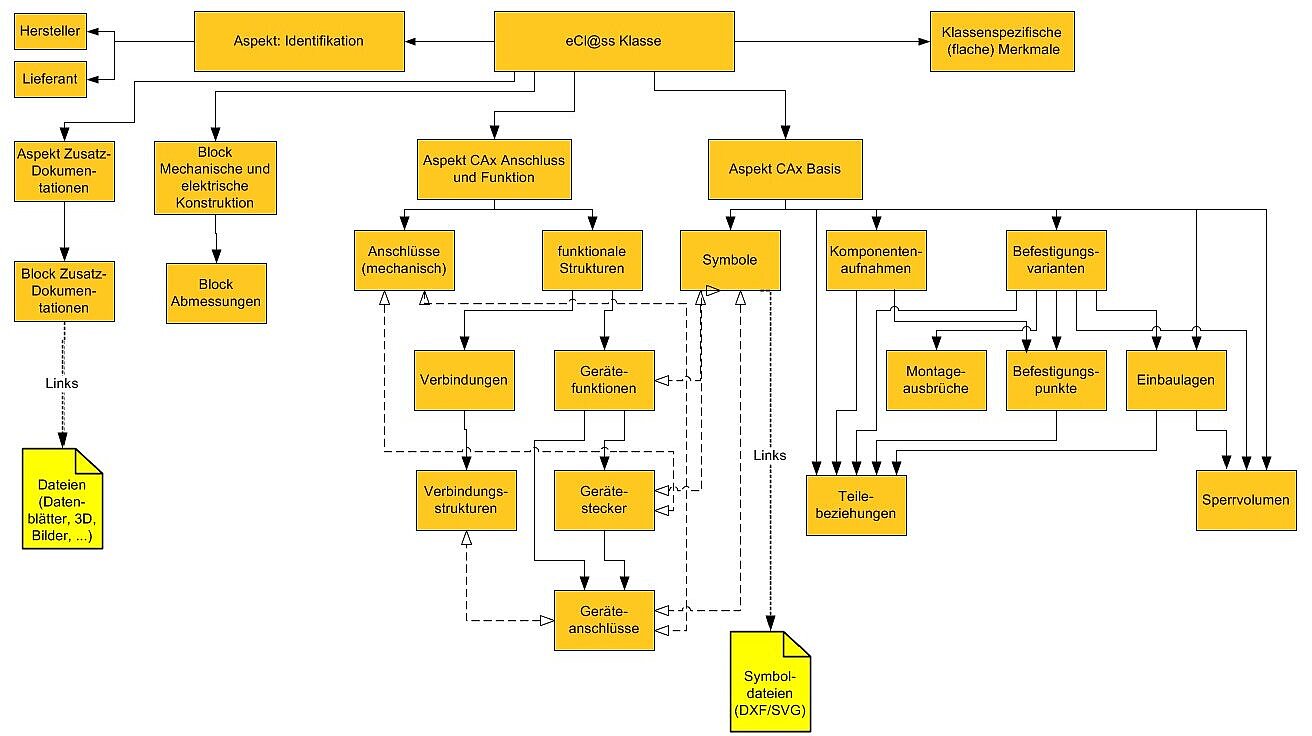

The following layout contains all relevant information requirements from the perspective of CAx applications.

The elements listed in the schematic are assigned to the ECLASS classes relevant to the CAE tools, and are used to enable the creation of data required by a CAE system for an assigned product. The schematic shows the essential elements within the individual aspects in order that the relationships can be mapped. The blocks, which are connected with lines, are directly contained in the respective block, dashed lines indicate connections where information from one block is being referenced in another block. For example, all connections to a device are described in the Connections (mechanical) block, and each connection is issued with a connection ID for clear identification. If the function of a device is now being described, a part of this description also includes information on which device connection is required. To avoid maintaining the required data anew, the connection ID is used to create the reference to the real connection.

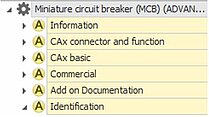

The following general advanced aspects are included in every ECLASS class:

- Information

- Identification

- Commercial

- Additional documentation

The following "CAx" aspects and the blocks are only contained in the classes in which CAx-relevant products are described:

- CAx connection and function

- CAx basis

- Mechanical and electrical design (block)

Example:

The violet frames show general advanced aspects and blocks.

The violet frames show general advanced aspects and blocks.The red frames show the additional CAx aspects and blocks.

The green frame shows class-specific technical characteristics.

Use of structures in relation to the applications

- Engineering (product selection, ...)

- Circuit diagram

- Drilling

- Routing

- ...

To be supplied later